PID control

PID is a "closed loop" control algorithm (instructions for solving a task) used to adjust a control value, (eg a idle valve position). In order to process actual values (eg engine speed ) to match the desired TARGET value (eg, idle speed ) then adjusts the PID-algorithm control value according to these three elements.

Summary

P is used to bring the value close to the target.

I is used to bringing the error to zero.

D is used to dampen the response.

Setup process

P and I must always be used (not allowed to be zero), D is optional and not always necessary.

•Usually starting by increasing the P and I together (using the same values) until it becomes slightly unstable.

•Bring in some D to counteract that, and then fine-tune each value. Often by reducing P and increasing I.

•The overall goal is to use as high values as possible while still having a stable response.

•Then decrease all values a bit to add some safety margin to prevent overshoot or oscillation.

Typical problems (P)

•Too low: Does not reach target, slow response.

•Too high: Fast oscillation.

Typical problems (I)

•Too low: Does not reach the target, slow response, overshoots and recovers slowly.

•Too high: Oscillation.

Typical problems (D)

•Too low: Overshoot.

•To high: Oscillation.

Example

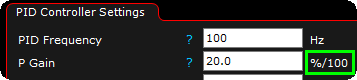

The above "%/100" means % per 100 error.

Example: 100 error --> 100% duty outputed.